Strona główna / Cooperation

Start your journey to optimal plastic product manufacturing

Begin cooperation with Plastipol and save

on recurring production runs.

Better results through the optimization of plastic product manufacturing

Every day, medium and large industrial companies order millions of plastic products, and these orders can either help their growth or lead to expensive delays.

Our experience has shown that the most successful companies take a strategic approach that involves three key elements:

1

matching the production technology

to their specific needs

2

maintaining high standards in production and materials

3

collaborating with a production partner who consistently meets deadlines

That's why we've developed a collaboration process that takes all of this into account, allowing your organization to achieve better efficiency.

Discover our collaboration process

Our collaboration process has a simple premise: to help you optimize the production of plastic products, you’ll receive maximum technological support from us at every stage of cooperation.

step one

3 minutes

Fill out the form

Fill out the form by sending us the product design you want to produce in recurring production runs.

step two

30 - 60 minutes

Phone call

You’ve sent us the product design? Great! Within 1 hour, you will receive an email from us with questions about the product. After receiving your answers, our consultant will get in touch with you and provide recommendations regarding material selection, form, and production technology.

This way, you’ll discover the cost-effectiveness of each option and the long-term benefits.

Need to change the design? No worries — we’ll make modifications at no extra cost! If we believe the production isn’t cost-effective, you’ll find out right away.

step three

Quotation

Having the necessary quotation, you will discover the actual cost of individual components, such as production cost, materials, molds, and post-production processing.

Do you want to compare production quotations in multiple technologies? No problem — we will prepare several quotations for you.

step four

Schedule and tooling

After accepting the quotation, we will assign you a dedicated Technical Advisor. We will establish a realistic production schedule and carry out tooling and prototypes.

The deadlines we provide are precise, so you’ll know exactly when the next stage will occur. Do you have any concerns about the prototype? We will make revisions until you approve the product.

step five

Starting the production series

We initiate the production series, ensuring high production and material standards. Each subsequent series is produced according to the established schedule.

No space for storing a large production series? Utilize our warehouse.

Check how much you can save on each production series.

What do you gain by collaborating with us?

Transparency in pricing

Local production

Optimization of the production process

Providing changes to the project

Product optimization - cost savings

Selecting the optimal material

Collaboration that brings benefits regardless of market fluctuations

Price fluctuations. Raw material shortages. Despite all these market uncertainties, by collaborating with Plastipol, you can be certain that we will not only promptly inform you about changes but also mitigate their effects.

An example? We can immediately order a larger quantity of material for you, which will result in triple benefits: a lower final product price, risk mitigation against price hikes, and accelerated delivery times for subsequent production batches.

Dedicated technical advisor

We’ll assign you a dedicated expert who will propose design changes, explain technical details, and ensure cost-effective production.

Throughout the project, they will continuously work to reduce waste, control costs, and eliminate the risk of producing faulty production batches. With their expertise, you’ll always receive prompt and insightful answers whenever questions arise!

What do you gain by cooperating with us?

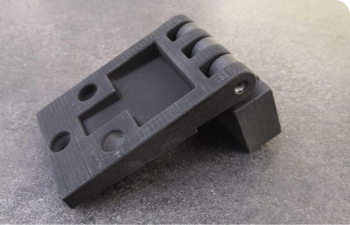

Mass production, serial production, or prototyping? With us, you can be sure that we will carry out production series using the optimal processing technology.

We will determine how to produce production series to minimize waste, reduce costs, and avoid incorrectly executed production runs.

We design and manufacture molds for mass production of products in technologies such as rotational molding, thermoforming, injection molding, and extrusion.

We create large plastic products for every industry where precision, durability, and cost optimization are essential.

Through injection molding, we manufacture highly complex products in a single technological operation.

Thermoforming allows us to reduce the time required to produce plastic products and minimize tooling costs.

Cost-effective production technology, perfect for manufacturing large-scale plastic products.

An ideal technology for large-scale production of long elements, such as profiles, pipes, or seals.

- you need cyclical production of plastic products (according to monthly or yearly demand)

- you want to produce small products or large-scale items

- you are interested in producing a production series based on a conceptual design or existing technical documentation (drawings, 3D models)

- you need products that are readily available on the market (e.g., in catalogs or stores), such as bottles, containers, or food storage containers

- you want to produce a one-time production series

- you need a small production series.

From medium-sized facilities to large industrial enterprises, discover why companies choose Plastipol.