Strona główna / Services / Plastic production

Plastic production

We manufacture production series using various processing methods. Production can be done in one of three ways.

Ordering plastic production

We manufacture plastic production series through a predetermined schedule. This ensures that product production is appropriately planned.

We can handle material orders and production planning to deliver the right number of products to our customers precisely when they need them.

Types of plastic production

Serial production

Serial production is a broad term, and depending on the shape and desired properties, any of the plastic production technologies can be applied to it.

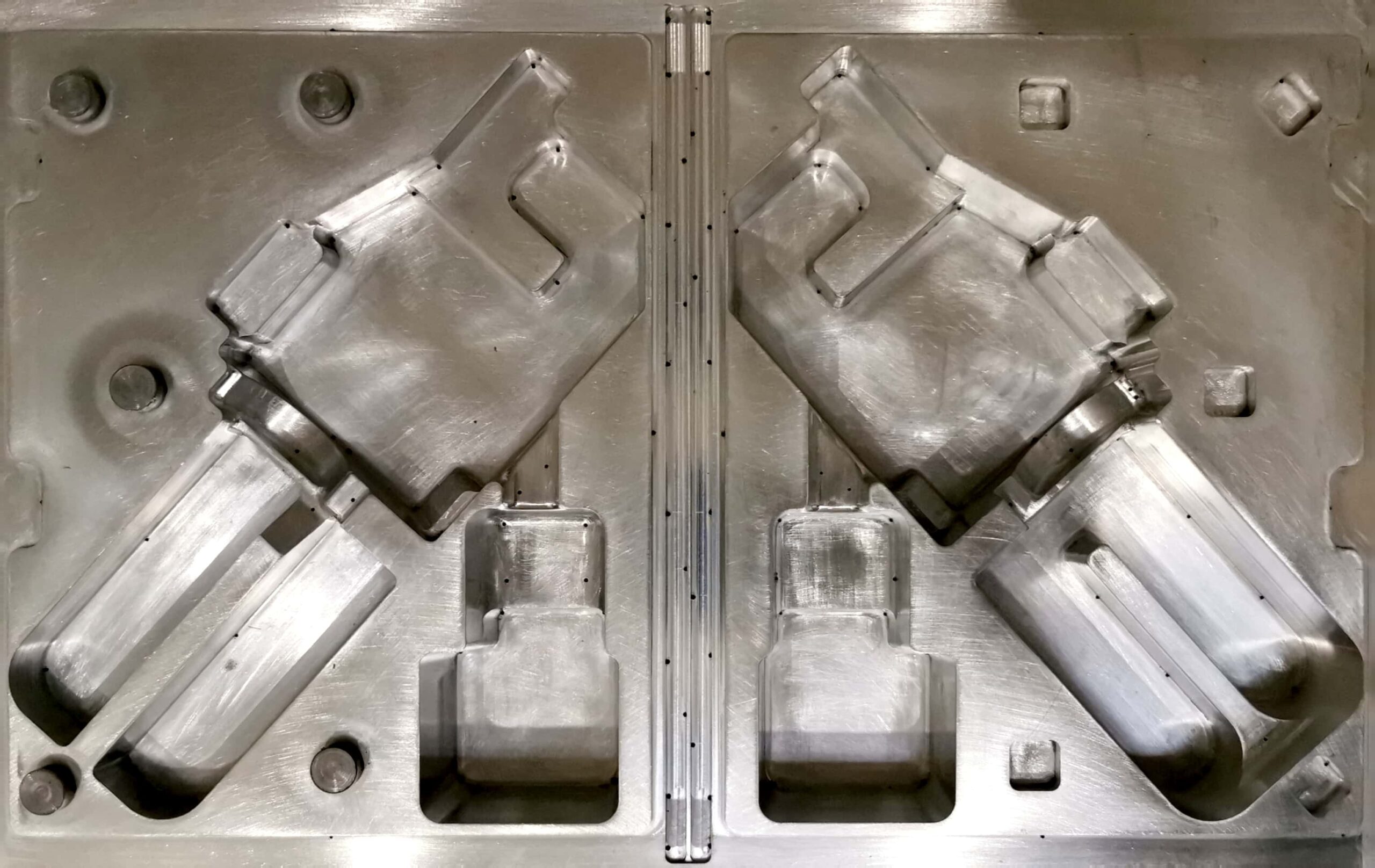

In case of serial production, compared to prototyping, we often utilize technologies that require the use of molds.This approach is justified and cost-effective since the mold cost

is spread across all the products.

Mass production

In mass production, the number of products to be manufactured starts from tens of thousands, and even millions. Therefore, it becomes cost-effective to invest in expensive tools , which results in a lower unit cost for each product.

Mass-produced products are often used in industries such as automotive manufacturing. This also applies to the production of packaging, containers, bottles, jerry cans, and caps. Commonly used technologies for mass production include plastic injection molding and extrusion.

Prototype production

In the plastics industry, it’s common to create a prototype before making the final product. The prototype helps to check the design, its strength, and other important factors.

In the case of mass production, compared to prototyping, we often utilize technologies that require the use of molds. This approach is justified and cost-effective since the mold cost

is spread across all the products.

Do you have any questions?

At Plastipol, we specialize in the production of plastic products. Just share your needs with us, and our team of specialists will take care of selecting the right technology for you

The types of plastics we use in plastic production.

We can practically use all available plastic materials in production.

Some examples of plastics we use include polyethylene, polypropylene, polyvinyl chloride, polystyrene, ABS, and others. Depending on the technology, the input material can take the form of products such as sheets, foil, granules, powder, filament, and more.

Plastic

production

On the molds we previously created

We handle the whole process to ensure a smooth coordination between mold production and plastic product manufacturing, making necessary adjustments without unnecessary delays.

On the molds provided by the customer

It's crucial for us to have a precise understanding of the mold's specifications to determine if we can undertake the project and plan the plastic production process accordingly.

Without mold production

Sometimes, there's no need to create a new mold. This happens in situations where we can utilize a mold that we have previously made

Plastic processing at Plastipol

Thanks to our extensive technological capabilities, we can accommodate nearly any plastic project based on specific needs and applications. We utilize four production technologies: injection molding, extrusion, rotational molding, and thermoforming.

Understanding the purpose of a particular product allows us to provide suitable advice on making changes to adapt the technology to the project. Our key focus is to ensure that production is optimal both economically and technically. Our modern machinery park plays a significant role in helping us produce high-quality plastic products.

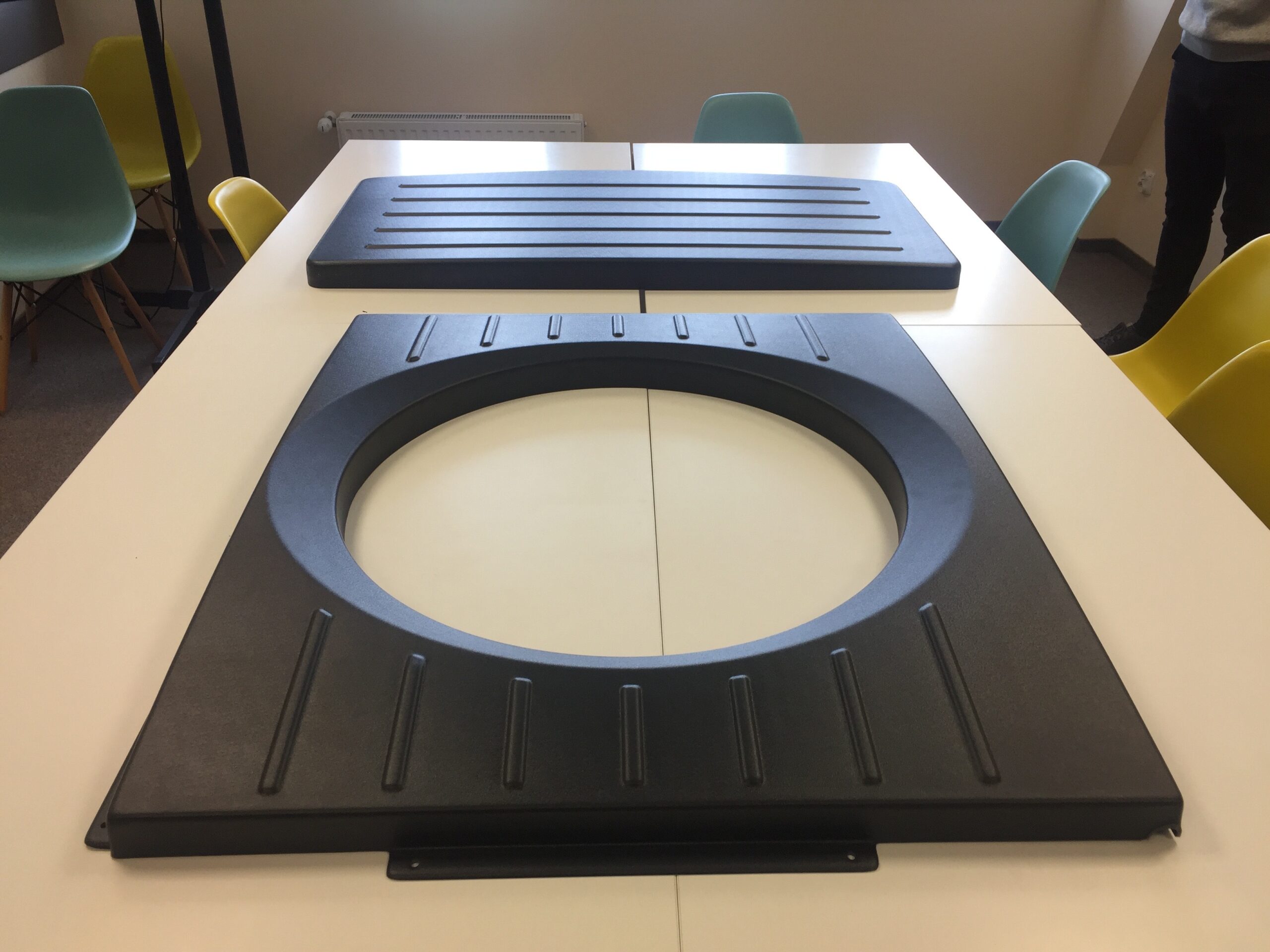

We manufacture both industrial and visually attractive products.

The production of industrial products, such as machine and equipment components, requires a high level of precision. We always tailor the appropriate technology to meet the specific needs, and we also manufacture necessary tooling, such as molds, to produce components within the required dimensional tolerance.

When it comes to producing visually attractive products, the key aspects include the choice of material, its structure, and the surface finish. Precision often takes a secondary role. It is also essential to ensure that there are no visible traces on the product’s surface due to technological aspects. When manufacturing aesthetic products, our goals and priorities are entirely different from those for industrial products.

We specialize in manufacturing, among other things:

Machine and equipment components

tanks

manholes

enclosures

profiles

covers and shields

packagings

plastic containers

plastic boxes

interior furnishings components

spacers for the construction industry

medicine containers

With Plastipol, you gain not only full control over the production process but also the assurance of a high, Polish standard of design and production.

Circular economy

We’re following the current trend of recycling resources, which benefits the environment. This is a crucial consideration for both domestic and international production. That’s why we prioritize eco-friendly practices and can provide products made from recycled plastics, suitable for various applications.

Recycled plastics have a wide range of applications in the plastics production industry today. We also frequently recommend biodegradable plastics, which, unlike standard plastics, are environmentally friendly and not harmful to the environment.

Based on

customer's requirements, we select the appropriate material for a specific application.

These requirements can include factors such as resistance to moisture, chemicals, lubricants, oils, high or low temperatures, and more. We often use additives to modify the basic properties of plastics, such as enhancing UV resistance, increasing abrasion resistance, hardness, and so on.

We often receive a sample of the desired product. In such cases, we select a similar material for the application. If necessary, we can also choose a material that has been certified for food contact use.

From medium-sized facilities to large industrial enterprises, discover why companies choose Plastipol.

Frequently Asked Questions

We create customized designs to meet the individual needs of our clients. We manufacture a wide range of products, including both industrial and visually attractive items, varying in size from small to large. Thanks to our diverse range of technologies, we have broad manufacturing capabilities.

We do not manufacture standard products such as bottles, containers, food storage, etc., as they are readily available in various product catalogs on the market.

We create customized designs to meet the individual needs of our clients. We manufacture a wide range of products, including both industrial and visually attractive items, varying in size from small to large. Thanks to our diverse range of technologies, we have broad manufacturing capabilities.

We do not manufacture standard products such as bottles, containers, food storage, etc., as they are readily available in various product catalogs on the market.

We do not have catalog products; our production is always tailored to the individual needs of our customers.

We can use any plastic materials available on the market for production.