Polyethylene (PE) is a commonly used thermoplastic polymer that has found widespread applications in various fields of the plastic industry. In this article, we will take a closer look at this versatile material, discussing its properties, uses, and various processing technologies.

By reading the article, you will learn:

- The properties of polyethylene

- Types of PE and the applications of polyethylene

- Advantages and limitations of PE material

- Manufacturing technologies

Properties of PE

Polyethylene is a synthetic material characterized by a range of properties that make it an attractive choice for many applications. Below are the key characteristics of PE:

- Low Density: Polyethylene has a low density (ranging from 0.910 to 0.930 g/cm3), making it lightweight, which is highly advantageous in many applications such as packaging, sports equipment, and constructions where weight is a critical factor.

- High Tensile Strength: Polyethylene has good tensile strength, making it a durable material in various applications such as packaging, pipes, and structural components.

- Chemical Resistance: It is resistant to the effects of chemicals (alkalis, acids, and salts), making it useful in the chemical industry for producing containers for chemicals and in other applications where contact with aggressive substances is possible.

- Excellent Electrical Insulating Properties: It has good insulating properties, making it useful in the electrical and electronic industry for manufacturing wires, cables, and other components that require insulation. It is also used in the production of coatings for electrical wires.

- Flexibility: Polyethylene is flexible, which means it can be used to produce flexible components such as flexible pipes or packaging with variable shapes.

- UV Resistance: Polyethylene is relatively resistant to UV radiation, making it suitable for outdoor applications such as garden furniture, toys, and architectural elements. PE does not lose its properties when exposed to sunlight.

- Low-Temperature Resistance: Polyethylene retains its mechanical properties even at low temperatures (down to -50°C), making it suitable for products that will be used in colder conditions.

- Excellent Slip Properties: The excellent slip properties of PE result from its chemical structure, enabling smooth movement inside molds and on surfaces. This significantly facilitates manufacturing processes, processing, and applications in packaging, engineering, and the food industry.

- Ease of Processing: It is relatively easy to work with and process, making it a good material for various production processes, including injection molding, extrusion, and of course, rotomolding. This material is also used as components in packaging machinery.

- Physiological Neutrality: Due to this characteristic, polyethylene is approved for contact with food, making it widely used in industrial packaging production and products for the food sector.

- Low Wear Resistance: This characteristic is a result of the molecular structure of PE, which translates into minimal wear during contact with other surfaces, making it an ideal choice for applications requiring minimal friction and long-lasting durability.

- Recycling: Polyethylene is relatively easy to recycle. During disposal, it does not release harmful compounds.

Applications of polyethylene

Polyethylene plastic is a material with a wide range of applications. It is used in many industrial sectors due to its versatility and unique properties.

Don't wait!

Tailor the technology to your needs to reduce plastic production costs.

Packaging sector

In the packaging sector, it is used for the production of packaging foils, bags, garbage bags, and bottles.

Food industry

PE is often used as an alternative to cardboard containers in the food industry.

Water and Sewage Industry

In the water and sewage industry, HDPE pipes are used in water and sewage pipelines due to their durability and corrosion resistance.

Other sectors

Polyethylene (PE) is used in practically every branch of industry. It is a material used in the rotomolding process, which is why items such as garden furniture or products for children, like slides and pools, are made from PE. Additionally, polyethylene is resistant to weather conditions, making the items ideal for outdoor use. PE is also found in medical products, pharmaceutical packaging, automotive components, and many others.

Different types of PE – HDPE/LDPE/LLDPE

There are various variations of PE. Polyethylene is a general term for a family of polyethylene polymers. Below, each of the 3 variations of PE is described:

HDPE (High-Density Polyethylene) is a type of polyethylene with high density:

HDPE (High-Density Polyethylene) is characterized by higher density compared to other forms of polyethylene. It has excellent mechanical strength and rigidity. High-density PE is used in the production of chemical containers, pressure pipes, food packaging, bottles for liquids, and other products that require durability and resistance to external conditions.

LDPE (Low-Density Polyethylene) is a type of polyethylene with low density:

LDPE (Low-Density Polyethylene) is characterized by lower density compared to HDPE. It is an amorphous polymer and is more flexible, elastic, and soft. LDPE is used in the production of packaging films, garbage bags, household items, toys, as well as extruded bottles and containers with lower mechanical strength.

LLDPE (Linear Low-Density Polyethylene) is a type of polyethylene with linear low density:

LLDPE (Linear Low-Density Polyethylene) is a type of polyethylene with a linear structure and low density that falls between LDPE and HDPE. LLDPE combines the flexibility of LDPE with the greater mechanical strength of HDPE. It is used in the production of packaging foils, garbage bags, flexible tubing, recreational equipment, and other products that require flexibility and durability.

Advantages and Limitations

Polyethylene has many advantages that have contributed to its wide use in the industry. Its low density makes it lightweight, which is particularly important in products where weight is a significant factor. Additionally, PE is known for its durability, chemical resistance, and flexibility, making it an ideal material for use in various environmental conditions. However, this material has its limitations, such as limited resistance to high temperatures and certain chemicals, which may affect its use in specific applications.

Polyethylene Processing Technologies

Polyethylene is a versatile material that is easy to process, which is why it is used in almost every technology we offer:

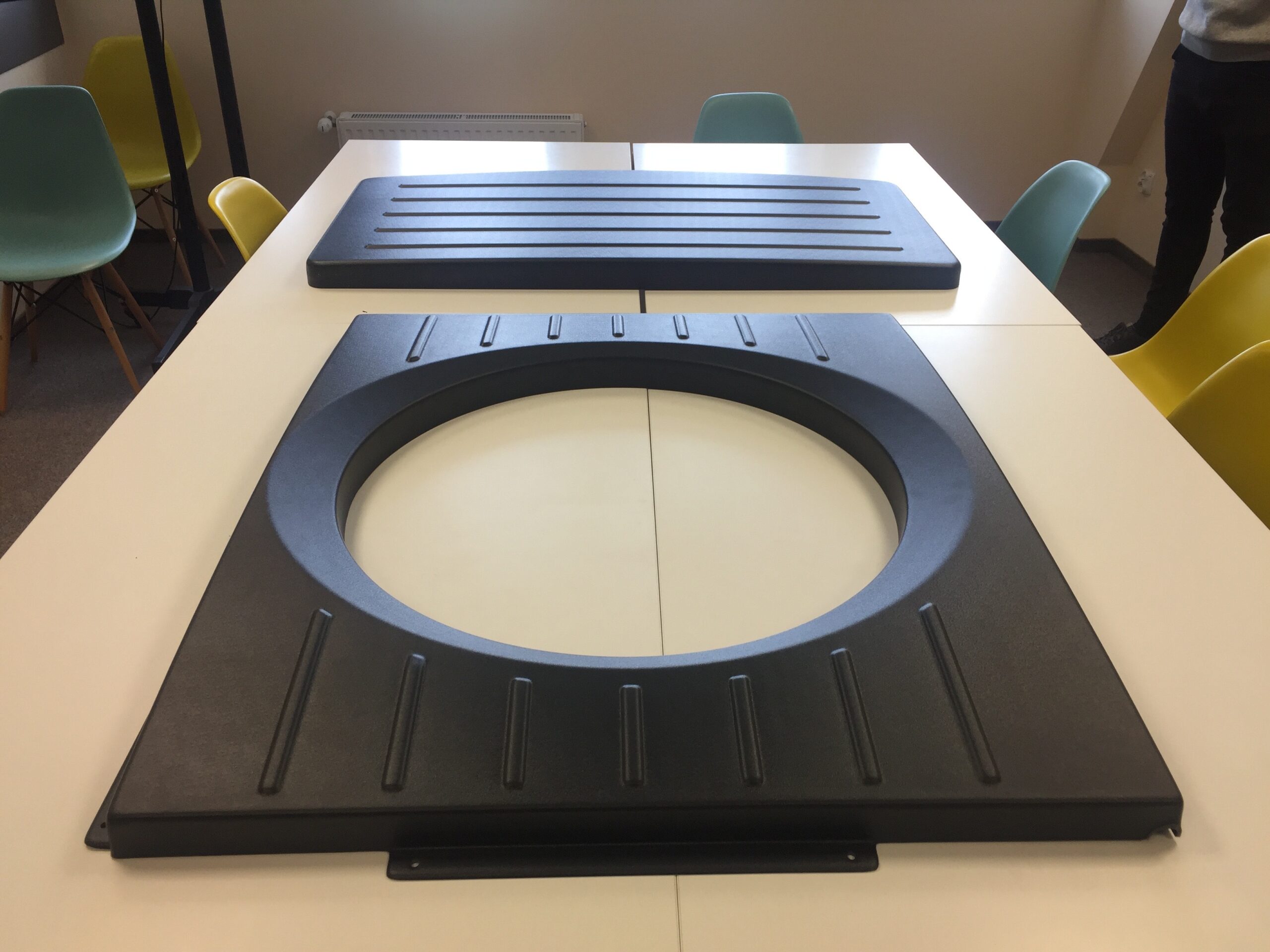

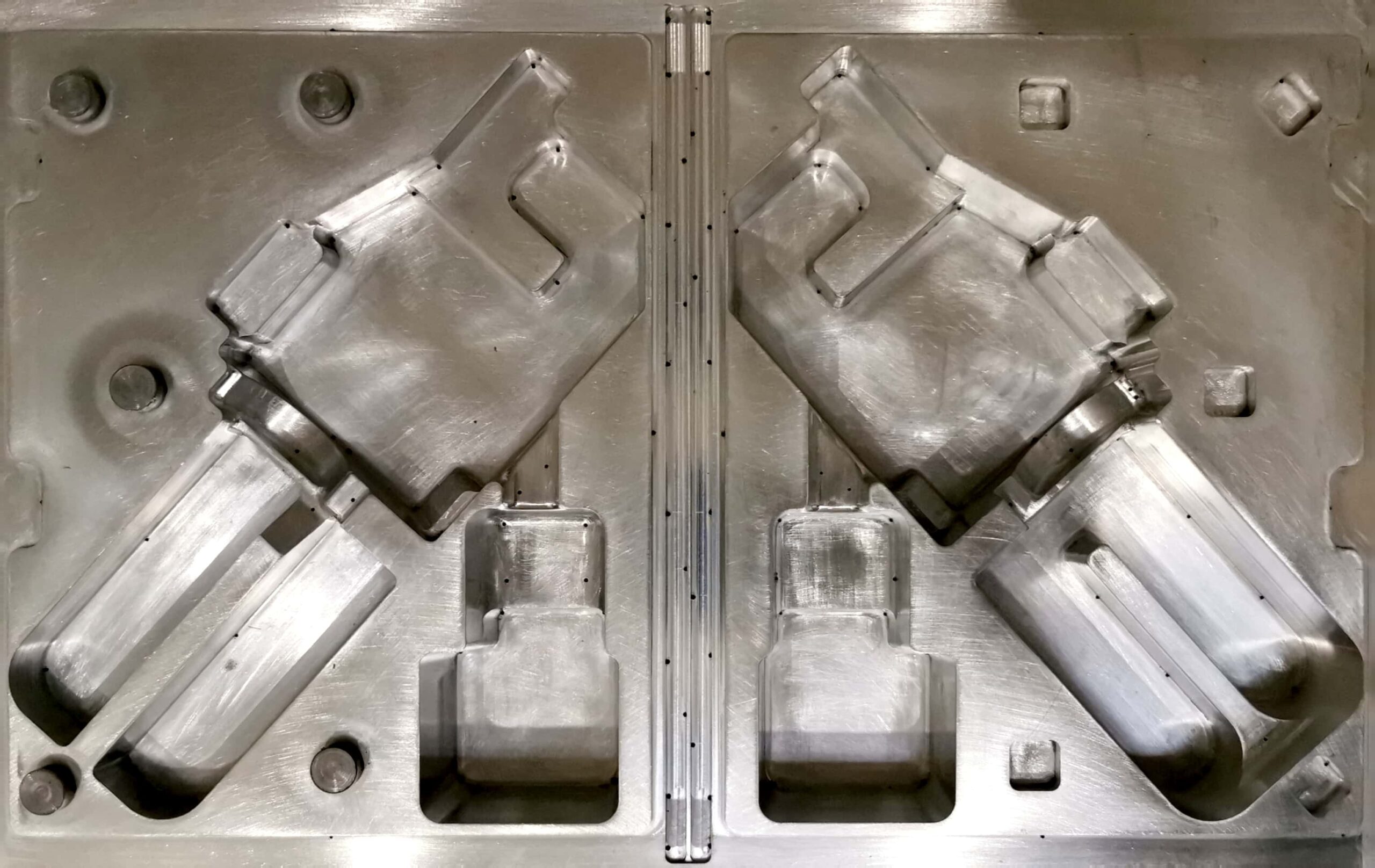

Injection molding

One of the most popular plastic processing technologies is injection molding. Its significant advantage is the ability to produce parts with complex shapes. It is dedicated to large production series (10,000 pieces per year and more). This technology is used to produce items such as gears, plugs, packaging, toys, and household articles.

Extrusion

A characteristic feature of this technology is the ability to produce parts with a constant cross-sectional shape only. This technology is used, for example, to produce profiles and pipes.

Rotomoulding

PE is used as the target material in over 90% of cases in this technology. You can read more about the specifics of rotational molding here. This technology is used to produce items such as life buoys, slides, and various types of containers used, for example, in wastewater treatment plants.

Thermoforming

The material in this technology is available in the form of sheets of the appropriate size. This technology is used, for example, to produce blister packaging, food packaging, or buffer covers.

CNC machining

Used as a prototype before mass production. This technology is used, for example, to produce spacers or bearings.

Summary

Poliethylene (PE) is one of the most important materials in today’s plastics industry. Its variety of types, unique properties, and wide range of applications make it an integral part of many everyday products. As processing technologies and sustainable production continue to evolve, polyethylene is expected to play an even greater role in shaping the future of the plastics industry.

Are you wondering if PE material is suitable for your project? Consult your project with us, and our engineers will surely provide an answer as to whether PE is a suitable material for your application.