Introduction to rotational molding.

Rotational molding, also known as rotomolding or rotational casting, is one of the fastest-growing methods in the processing of plastics. It’s easy to understand why. Rotational molding techniques, combined with used polyolefin powders, can be employed to produce hollow objects of any size and diverse geometry – whether open or closed. In recent years, rotational molding technique has been extensively developed. On the production line, this process can now compete with or complement processing methods such as:

- blow molding,

- injection moulding,

- thermoforming,

- laminating.

Rotational molding began its development in the early 20th century. However, it was only in the early 1960s, when LyondellBasell replaced plastisol resins with polyolefin resins, that rotational molding gained popularity in the industry. Over the next few years, the development of specially designed low and high-density polyethylene for rotational molding allowed it to enter markets where resin parts and processes could no longer compete. At the beginning of the 1970s. Networked and modified polyethylene types entered the rotational molding market. These new powders opened up more market areas, especially in the production of large containers. “Linear low-density polyethylene for rotomolding was developed in the late 1970s and 1980s.” They brought about a rapid increase in the use of non-polyethylene resins, including nylon, polypropylene, and polycarbonate, for rotational molding.

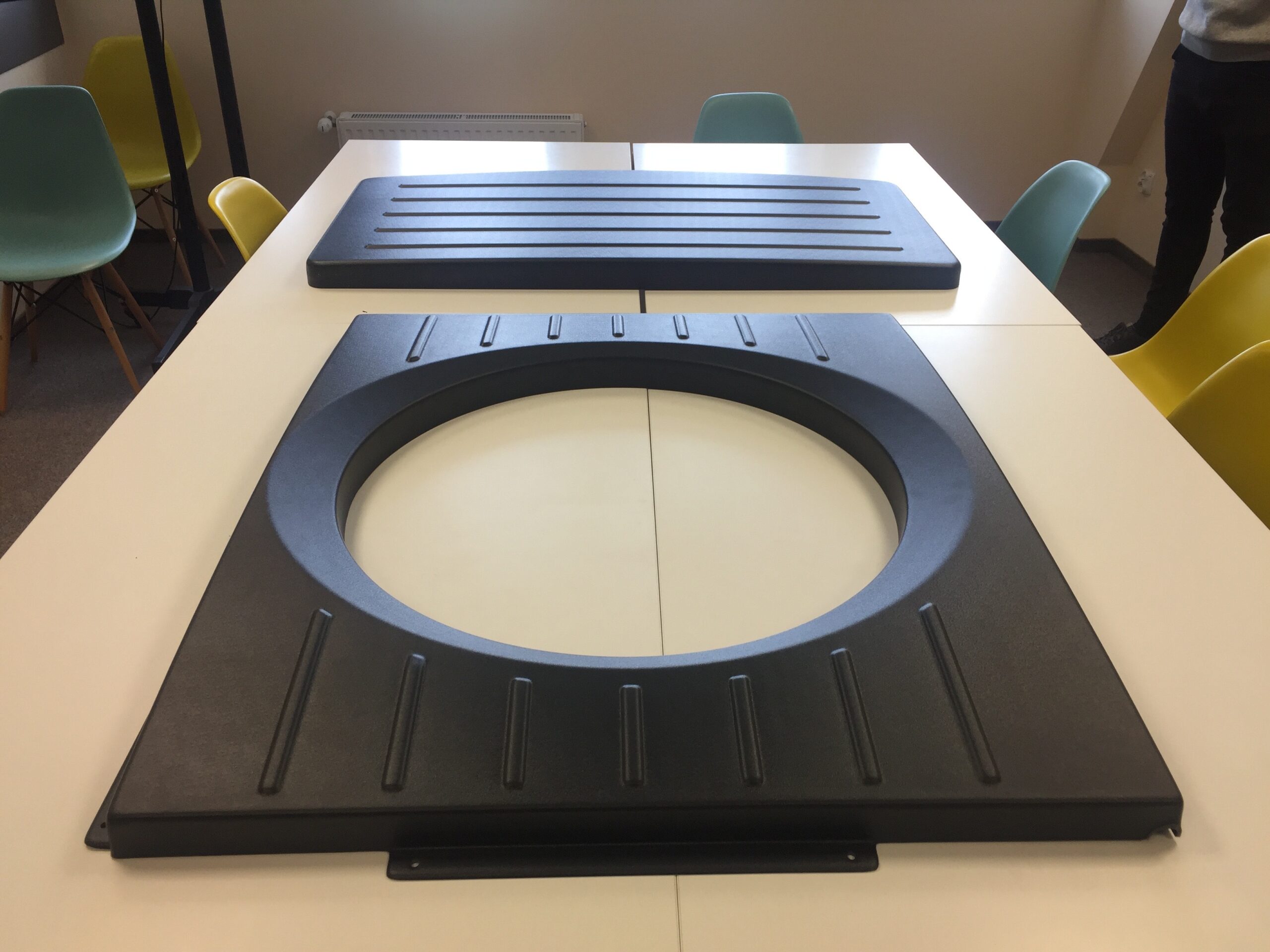

att. 1 Smaller rotational molded tanks – two-part.

Rotational molding is unique.

The main difference between rotational molding and other plastic molding techniques, such as blow molding, injection molding, vacuum forming, or lamination, is as follows:

- the raw material used for the process is powder – unlike in other technologies where granules or sheets are utilized,

- the material melts in the mold solely through the application of temperature – not pressure,

- the mold rotates on multiple axes,

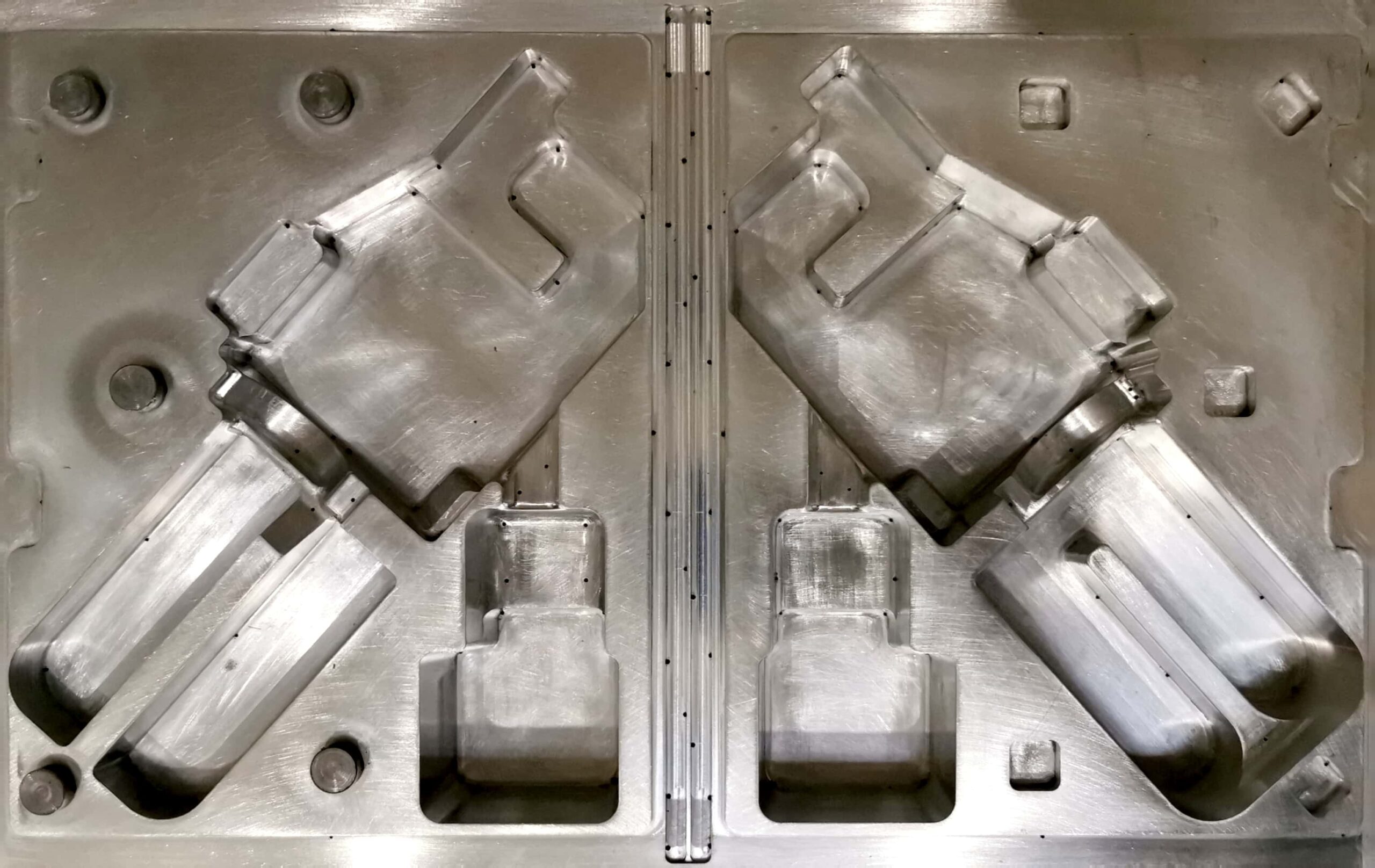

- rotational molding molds (despite their large size) are cost-effective compared to other technologies,

- working pressures are relatively low, meaning the product will not have additional stresses and will exhibit high strength throughout its geometry.

att. 2 Rotational molded products come in various sizes and geometries.

Processing and materials in the manufacturing process.

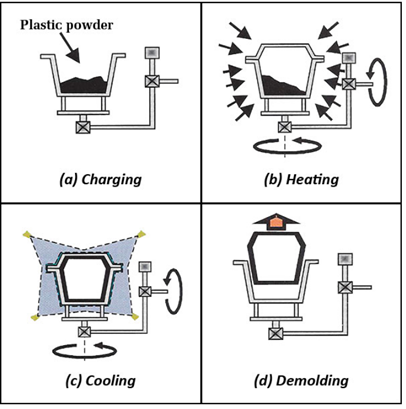

The concept of rotational molding is very simple. The plastic, in powder form, is placed inside a hollow mold, typically made of cast aluminum or fabricated from steel sheet. The mold is closed and slowly rotated on two axes. The mold is then heated in an oven while rotating, and the polymer gradually melts and ‘coats’ the inside of the mold. After complete melting of the polymer powder, the mold is transferred to a cooling station and cooled typically with air, and sometimes with a fine mist of water. As the mold cools, the material solidifies. When the material cools sufficiently to release from the mold surface, the process is halted, and the product is removed from the mold.

att. 3 Diagram of the rotational molding process

There are many variables that can affect production and the final product, such as ambient temperature and humidity, mold type, material specifications, and powder quality.

Currently, the industry heavily relies on polyethylene (PE), with 97% of rotationally molded products being made from this material. Polyethylene is a versatile, easily moldable, and readily available polymer that has dominated the process. Rotomoulding is a casting technique where powder is almost always used instead of pellets, which means that the material must be ground. Polyethylene is relatively easy to grind at room temperature. The most commonly used types of polyethylene are:

- LDPE(Low-Density Polyethylene)

- LLDPE (linear Low-Density Polyethylene),

- HDPE (High-Density Polyethylene).

The development of other polymers was hindered by the fact that the process is relatively long and thus aggressive towards polymers. However, there is some application of PVC (usually in the form of liquid plastisol), polypropylene, and polyamide (PA6, PA11, and PA12). Many of these non-polyethylene materials are challenging to grind, and most of them require processing into powder through cryogenic milling – a freezing grinding process that is more costly. There is a desired growth in research and development efforts to expand the range of materials available for the industry.

att. 4 – LDPE powder

Advantages and Disadvantages of the Process

Rotational Molding – Advantages

- the relatively low cost of production preparation, attributed to the affordable manufacturing of foundry molds,

- waste-free processing method,

- the ability to attach additional elements (bushings, pins, sleeves, rings) in the mold, which are covered with molten material and become integral parts of the casting after the process is completed. There is also the option to incorporate reinforcing ribs in the mold, enhancing the rigidity of the walls for very large castings.

- the entire process (heating, melting, molding, and cooling) takes place within the mold and does not involve any external pressure. There are no seam lines on the surface of the products.

- the capability to produce objects with a mass ranging from tens to several hundred kilograms, which is not achievable in injection molding or extrusion technologies due to the structural limitations of these processing machines.

Rotational molding – disadvantages

- relatively long cycle time for casting production – low efficiency.

- low efficiency and high energy consumption of the process, caused by heating and cooling the mold using air.

- the cost of preparing materials is further increased by the necessity of converting them into powder or pellets.

Products manufactured using rotomolding

This exceptionally versatile technology can produce an incredible variety of products. There are thousands of rotationally molded products used in various sectors. Key areas include:

- tanks for water and chemical storage – up to 50,000 liters,

- products for material transport, such as containers, crates, pallets, as well as insulated containers for fish and refrigerators,

- environmentally friendly products, including waste bins, road bollards, posts, traffic dividers, and road signs,

- floats, buoys, and pontoons,

- automotive products, such as fenders for heavy-duty trucks, conduits, diesel fuel tanks, toolboxes, and tractor dashboards,

- kayaks and boats,

- outdoor use products, such as garden planters, water barrels, and furniture,

- toys and playground equipment.

att. 5 – Industrial products

In addition to these traditional areas, there is a significant increase in demand for innovative, design-based objects, including interior and exterior artistic items, lighting, and high-quality decorative products.

att. 6 – Sample decorative and utility products

In summary, one of the most respected pioneers in the industry, Professor Roy Crawford, summarizes the rotational molding process with the following words:

There is no doubt that the rotational molding industry has undergone changes and adapted its approach due to significant technological advancements in recent decades. Rotational molding has evolved from a manufacturing method perceived by many as a black art into a sophisticated process for creating high-quality products, some of which could not be produced using any other molding method.