Plastics are visible almost everywhere. Thanks to their innovation, it’s hard to imagine life without them. It may be nearly impossible. Plastics are composed of various types of polymers. Below, the definition of polymers and plastics is explained, and the most popular groups of plastics are presented.

While reading the article, you will learn:

- What is a polymer and a plastic?

- What are the types of plastics?

- What are the material groups?

- The advantages and disadvantages of plastics.

- What is their application?

- What impact do plastics have on the natural environment?

Polymer and plastic – definitions.

Polymers are high-molecular-weight compounds characterized by very large molecular masses. They consist of repeatedly occurring units called “mers.”

Depending on the type, polymers are produced through three chemical reactions:

- polymerization → This is a reaction in which monomers (simple molecules of the same chemical compound) combine to form a high-molecular-weight compound, which is a polymer. In this reaction, there are no by-products.

- polycondensation → During this process, it is possible for a reaction to occur with multiple molecules. A by-product (a simple chemical compound, e.g., H2O) is formed during this process.

- polyaddition → This is a gradual reaction that combines characteristics of both polymerization and polycondensation. In this reaction, there is no by-product formed.

Plastics are relatively new materials. They truly began to play a significant role in industry and everyday life only in the second half of the 19th century. Since then, they have played an important role in human life. Their unique characteristics contribute to improving human comfort and significantly increasing safety.

Plastics are materials composed of synthetic polymers (artificially produced by humans) or modified natural polymers. They may also contain various types of modifying additives, such as UV stabilizers, dyes, etc.

Types of plastics

There are many types of plastics. This is because, in addition to using basic plastics, there are practically unlimited possibilities for modification through special additives, enhancers, etc. For this reason, we can distinguish various types of plastics, which can be divided into many different categories. Below, we have described the most commonly recognized ones.

Classification of plastics based on processing properties:

Thermoplastic materials (thermoplastics)

A characteristic feature of thermoplastics is their softening and melting when exposed to heat. They can also be repeatedly processed.

Materials such as PE, PP, PS, PVC, PTFE, PA, PC, and ABS belong to this group.

If you’re interested in thermoplastic prices, please check here.

Thermosetting materials

Unlike thermoplastics, thermosetting materials become non-meltable and insoluble under high temperatures. Once they have cured, further processing is no longer possible. Materials in this group include phenolic-formaldehyde resins, urea-formaldehyde resins, and certain silicone resins.

Classification based on origin:

Synthetic plastics (polymeric materials)

These are materials that originate from chemical synthesis, meaning they are artificially created by humans.

Natural polymer materials (plastics)

They are produced by living organisms (e.g., cellulose, chitin, natural rubber)

Modified polymeric materials

These are natural polymers with modifying additives aimed at changing their utility properties. The possibilities of adding various modifying additives are practically unlimited.

Classification of plastics based on topology:

Linear

These are plastics whose main chains are straight and have no branches.

Branched

These are plastics whose main chains are branched.

Ladder-like

These are plastics in which two parallel main chains are connected by side chains.

Cross-linked

These are plastics that form a three-dimensional network.

Don't wait!

Tailor the technology to your needs to reduce plastic production costs.

Classification of plastics based on internal structure:

Amorphous

Amorphous plastics are those with disordered internal structure and weak energetic interactions.

Examples of materials with such a structure include PS (polystyrene), PVC (polyvinyl chloride), PMMA (polymethyl methacrylate), SAN (styrene-acrylonitrile copolymer), and PC (polycarbonate);

Crystalline

The internal structure of crystalline plastics forms a spatial, ordered network, and their energetic interactions are strong.

Examples of crystalline plastics include PP (polypropylene), PE (polyethylene), PA (polyamide), POM (polyoxymethylene), and PEEK (polyether ether ketone).

Classification of plastics based on properties:

Elastomers

Elastomers are materials that, at room temperature, exhibit very large elastic deformations (up to several hundred percent) and return to their original state after deformation. Elastomers can be given various desired shapes during processing.

Plastomers

Plastomers are further divided into subcategories. Here, we distinguish between thermosets (materials that transition from a plastic state to a hardened state – this process is irreversible) and thermoplastics, which are materials that, at elevated temperatures, transition from a solid state to a plastic state and then harden at lower temperatures (such as room temperature). This process is reversible, and thermoplastics can be subjected to processing multiple times. Multiple processing cycles make products more environmentally friendly.

Plastic groups along with examples

There are many groups of polymeric materials. The most popular ones include:

Polyolefins

This group includes PP and PE. They are among the most commonly used materials. Polyolefins are characterized by relatively high flexibility. Their disadvantage is that they have low rigidity and strength.

Polyamides

They form a broad group. Examples can include PA6 or PA66. Characteristic features of polyamides include high mechanical strength, high rigidity, and resistance to high temperatures.

Polyurethanes

This group includes materials like TPU. Polyurethanes are relatively easy to process and are characterized by high elasticity and vibration-damping properties.

Applications of plastics.

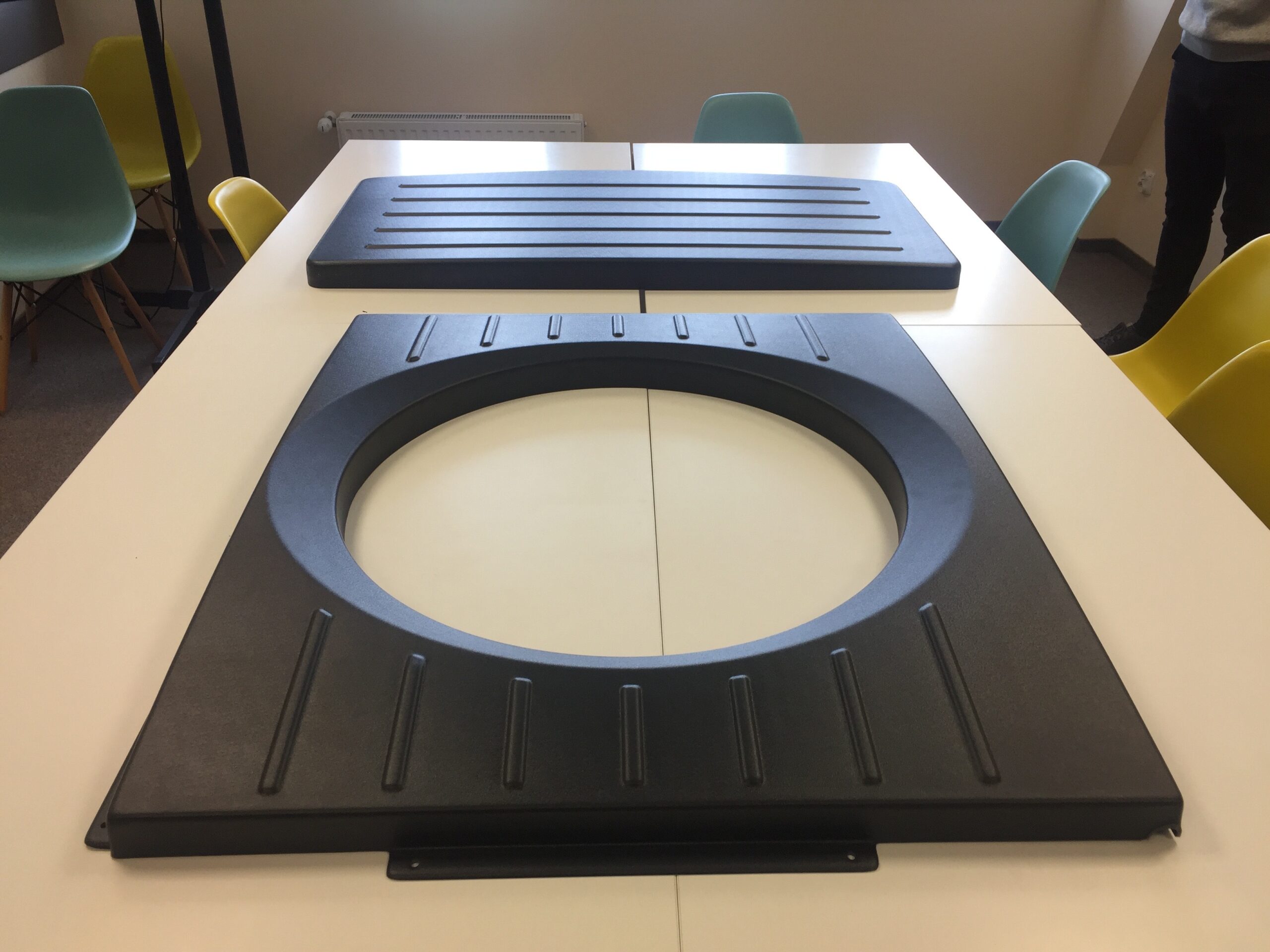

Plastics have a very wide range of applications and are used in almost every aspect of our lives. They often lead to the improvement of human life (protective helmets, prosthetics) and certainly make it much more convenient. There are many examples of their use, including the production of optical devices, packaging, film production, bottle manufacturing, gears, components in the electrical industry, and more. Many household articles are made from plastics, as well as toys, vehicle components, etc.

Don't wait!

Tailor the technology to your needs to reduce plastic production costs.

An increasingly common practice is also replacing other materials with plastics. However, it is always necessary to analyze whether it is feasible for a particular application. Changing the material group is not always possible. Plastics can replace, among others, steel, aluminum, wood, concrete, cardboard, laminates, etc.

In another post, you will find our article on the use of plastics in the heating industry.

Advantages and disadvantages of plastics.

Plastics are actually a group of thousands of different materials that have very broad applications. The properties of plastics are specific and unique compared to other materials, which is why they are difficult to replace. Their application also has disadvantages.

Advantages of plastics

Plastics are characterized by:

- Low density

- Low production cost

- Lack of corrosion susceptibility

- Diversity

- Recyclability

- aesthetics

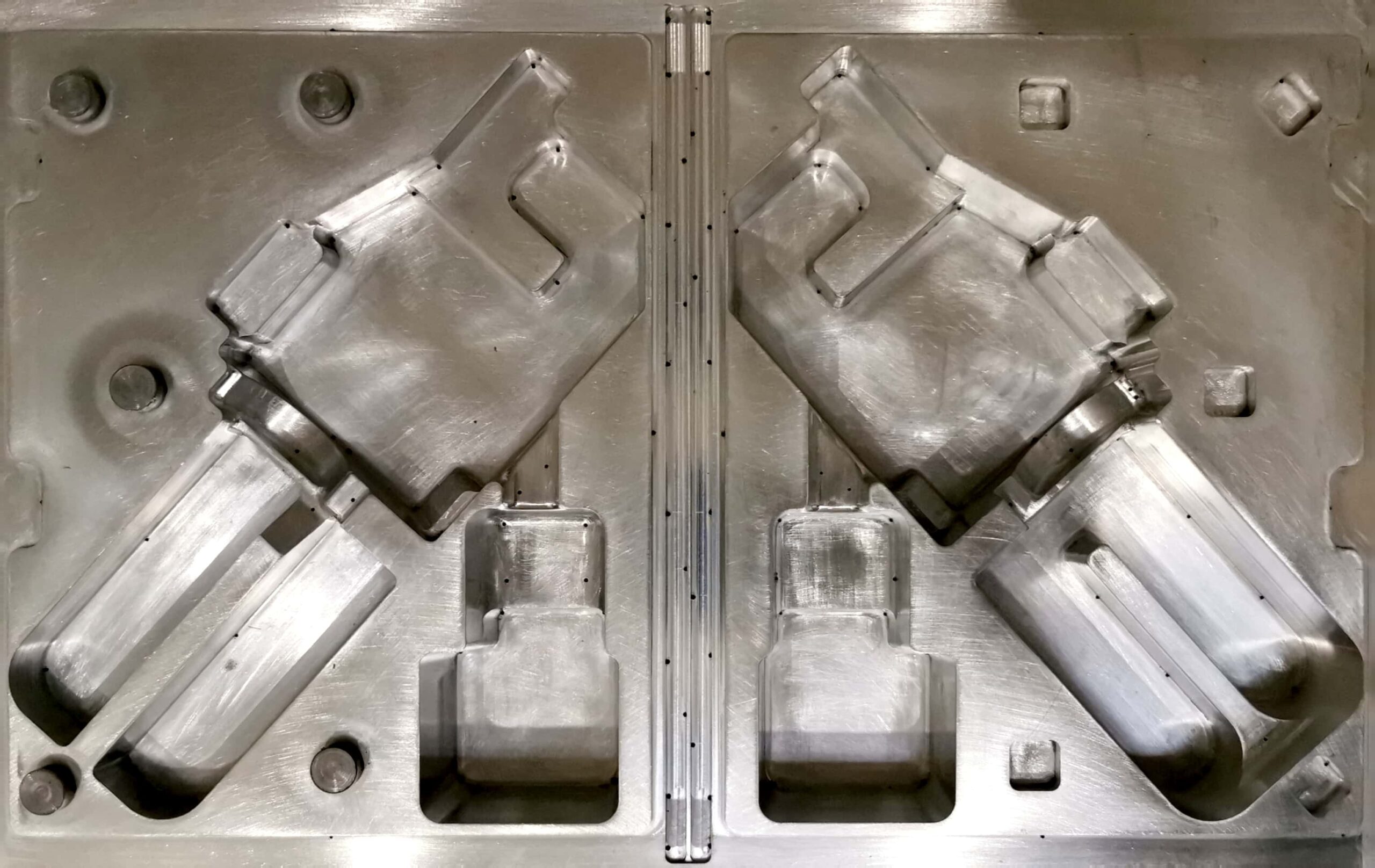

- Ease of processing and manufacturing

Disadvantages of plastics

Among the disadvantages of using polymeric materials are, for example:

- Lower strength (compared to other materials, such as steel)

- most plastics are produced from petroleum

- relatively long decomposition time

- low resistance to high temperatures (they can deform under the influence of heat)

We have described the detailed advantages and disadvantages of plastics in a separate article.

Plastics and the environment.

When approached thoughtfully, the utilization of plastics can have a positive environmental impact. This is achieved through practices such as efficient recycling and proper disposal. Here, we delve into a few crucial strategies for adopting a greener approach to plastic processing.

The use of regranulates

Regranulate is a secondary material that has been previously used to produce other products and then ground for reuse. This makes the use of the material in regranulate form a more environmentally friendly option than primary plastics.

Furthermore, the price of secondary material is lower, sometimes even by 20%.

More information is available in another article.

Producing durable products

Creating durable products reduces the negative impact on the natural environment. This is achieved through, among other things:

- Selecting the appropriate strength properties to ensure that products fulfill their function for an extended period

- Adding special additives, such as UV stabilizers, which allow products to be used outdoors for a longer duration

- Utilizing special coatings

Using biodegradable plastics

Biodegradable plastics are materials that undergo biodegradation and break down in a much shorter time frame than standard plastics.

Thanks to biodegradation, plastic objects and packaging can transform into water, carbon dioxide, or biomass. These materials break down due to the action of fungi, bacteria, air, water, light, or a specific combination of these factors.

Similar to traditional plastics, biodegradable plastics can be processed using all plastic processing technologies such as thermoforming, extrusion, or injection molding.

Biodegradable plastics have one key drawback for entrepreneurs – they are still more expensive than standard plastics.

Read the article What are biodegradable plastics and is it worth using them?

Summary

Plastics refer to a group of thousands of different materials with various properties. They are so unique that in some applications, they are difficult or impossible to replace.

The application of polymer materials is very broad, both in industry and in everyday items. Thanks to their low density (which results in low mass), plastic products are also easier to assemble. The lower weight of products also affects transportation costs.

In addition to their unique advantages, plastics also have their drawbacks. Their use is not feasible, especially in the case of very heavy loads. In such situations, very high mechanical strength is required, which can only be provided by metal components, for example. Plastics are also not suitable for working at very high temperatures.

The use of plastics does not have to be harmful to the environment. Utilizing regranulates, constructing durable products, or employing biodegradable plastics are important aspects for a more environmentally friendly production.

Are you considering plastic production? Consult your project with us and gain the necessary knowledge to determine its profitability.