Update – February 2024

Many people contact us with the intention of relocating production from China to Poland. We successfully implement such projects. However, there are situations where it is better to continue production in China. In this article, we will answer the question of when it makes sense to move production from China to Poland.

By reading the article, you will learn:

- When production in China is profitable, and when it is not.

- What aspects, besides price, should be taken into account.

- What does the relocation of production from China to Poland look like.

Production in China – costs

The price of products is just one of the costs that need to be taken into account in the calculation. Other significant factors include transportation, customs fees, customs clearance, and so on.

Cost of transportation

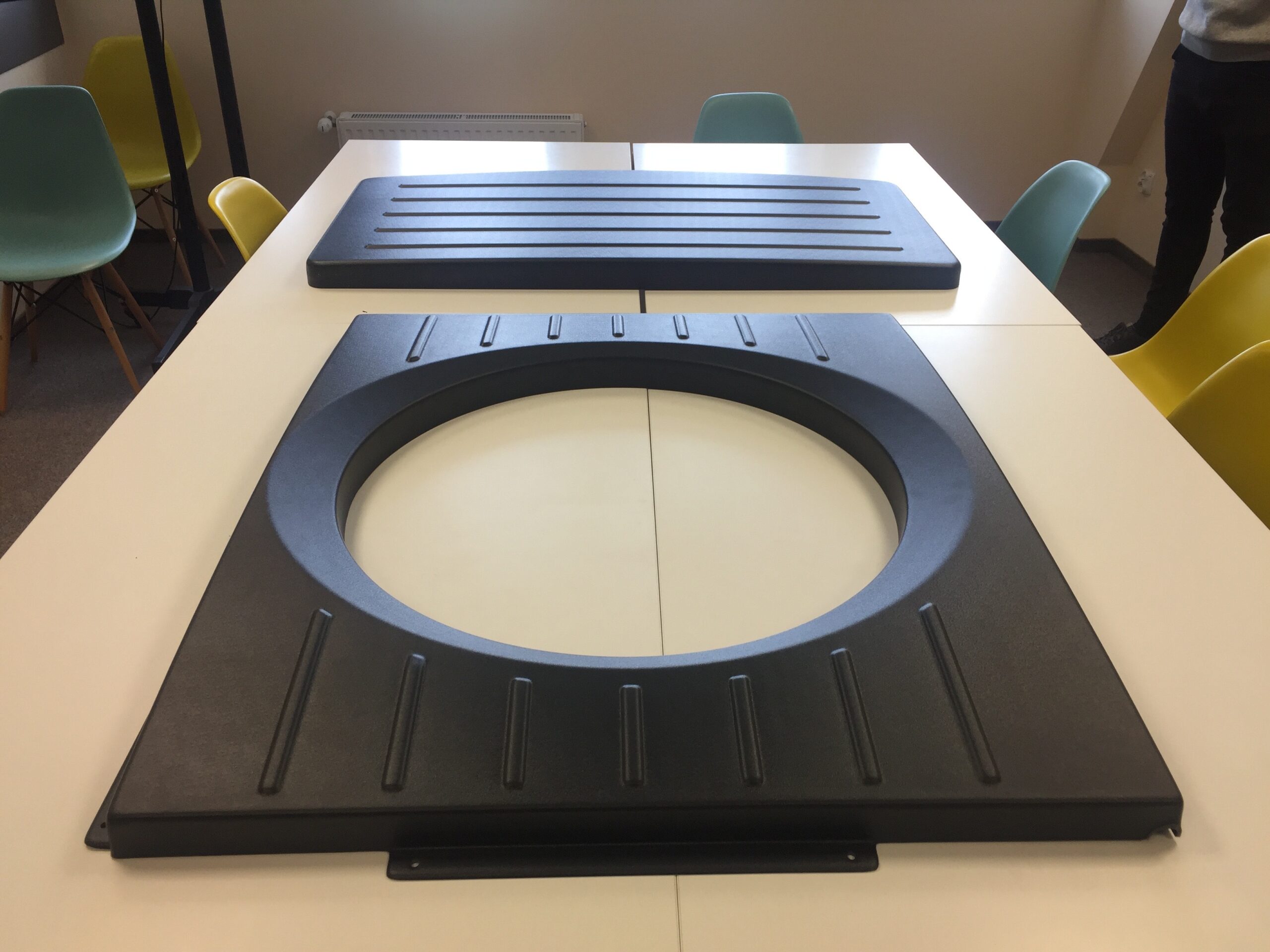

The most significant cost is transportation. It depends primarily on the size of the items and their quantity. The larger the volume of imported products, the higher the transportation cost. For this reason, production of large, hollow items in China is rarely cost-effective, while small, compact details are more so.

Customs rates – how much is the duty?

A very important factor is the calculation of duty. This cost can be of low value (0 or below 1%) but it can also be significant (70%).

The cost of customs duty can be checked in the ISZTAR 4 system. Here you can go to the tariff search engine. In the search engine, you can check the percentage amount of duty for a specific type of imported product.

The additional cost is the customs duty. The cost of customs clearance is not high. Its value is about 250 PLN.

Additional aspects

International trade with China is of course in accordance with the law (with the exception of some goods). It is important to remember the obligation to settle VAT. It should be charged and then deducted, the most cost-effective approach is to operate under procedure 33a, which means that we do not have to pay VAT first in order to recover it later. We must meet the appropriate conditions and prepare the relevant applications.

For small quantities, importing from China will rarely be cost-effective, whereas for mass production, it’s much more common.

For what products is production in China profitable?

Price is always a crucial factor. Often, it serves as a starting point for further discussion. It’s important to remember that production in China is not always cheaper. The situation varies between typical/catalog products and production for individual needs. An explanation of the difference between the two can be found in this article.

Typical/catalog products

Typical/catalog products are those that manufacturers sell to multiple customers. Examples include bottles, containers, food storage bins, trays, caps, buckets, and more. It is very rare to produce such products for individual needs because there are plenty of them available in the market, and it is usually not problematic to find the required shape and size. By using catalog products, there are no high initial costs associated with tooling.

Such standard, universal products are often worth producing in China. Due to the scale, the price can be much lower, and the variety much greater than in Poland or Europe. Certainly, for the import to be cost-effective, we need to meet the appropriate production minimums. For smaller batches, it’s better to seek ready-made solutions locally.

Custom Order tailored to individual needs

Typical/catalog products may not always be suitable. There is often a real and justified need to start plastic production for individual requirements based on your own drawing or 3D model. This allows:

- you tailor the plastic product to the device/machine/solution you are producing, not the other way,

- you can achieve savings in the long term,

- you have a unique, proprietary product that can feature your logo.

Sometimes, in-house production is the only solution because existing market products do not meet your needs.

For products tailored to individual needs, production in China is much less likely to be cost-effective than for typical/catalog products.

Production tailored to individual needs usually involves two stages:

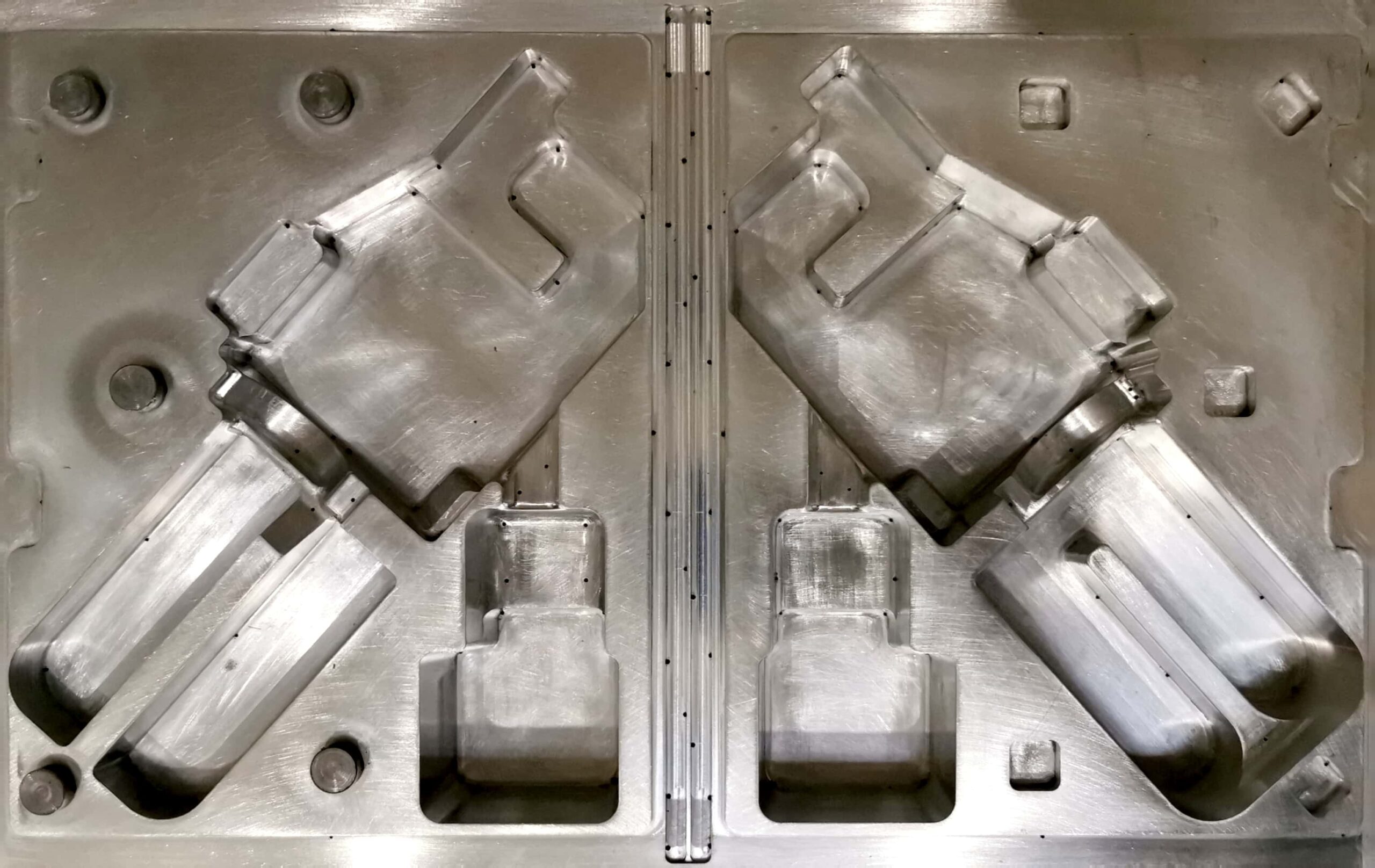

- Mold production (depending on the technology, this cost ranges from a few hundred to several hundred thousand PLN, typically several to tens of thousands of PLN).

- Manufacturing of production batches

Local serial production is usually cheaper, or at least price-competitive with Chinese production. The exception here is mass production (typically involving millions of units), where the price of imported products is more likely to be lower.

Mold prices in China can be significantly lower compared to local ones, especially in the case of multi-cavity complex injection molds.

For this reason, when it comes to production tailored to individual needs, we most often propose one of two solutions

- Making the mold in Poland, followed by local serial production.

- Making the mold in China, importing it, and then manufacturing production runs in Poland. At Plastipol, we also (with the client’s approval) import molds from China.

What aspects besides price should be taken into consideration?

Price is just one of the factors to consider when deciding on importing from China. Production in China comes with much greater risk than local production. We are talking about factors such as:

- currency risk (currency exchange rates are not stable),

- geopolitical risk (especially in the current context)

- fluctuating transportation costs from China

- longer lead times (much longer than local production)

- no insight into production and process control

- material composition may not comply with EU standards

- long and costly claims

- difficulties in communication

- Difficulties in verifying the supplier (the supplier may turn out to be unreliable)

Don't wait!

Tailor the technology to your needs to reduce plastic production costs.

What does the process of transferring production from China to Poland look like?

Above, we described which products are better suited for local production and which for import. Additionally, we identified factors beyond price to consider. In this paragraph, we will outline how the process of transferring production from China to Poland looks for two scenarios: when we own the mold and when a new mold needs to be created.

Transferring molds from China

If we were producing custom products in China, we probably also purchased molds. There is no problem with transferring the molds to Poland and starting local production on them However, it is important to remember to provide all the technical documentation for the molds.

Transferring production (we do not have molds)

However, most often, when producing in China, we do not own the molds. This happens when we did not incur a significant upfront cost. It means that the Chinese company has produced the molds at their expense. They can then sell the products not only to us but also to other companies. The second possibility is when we buy catalog products.

In such a situation, before starting production, you need to incur the upfront cost of producing the mold. You can find approximate mold costs in our FAQ section.

When calculating the transfer of production, it’s important to take this factor into account.

Summary

Due to the ongoing trend of deglobalization, companies are increasingly moving production from China to Poland. This is related to both production costs and risks influenced by factors such as wars, currency exchange rate fluctuations, lead times, costly claims, and more.

However, there are products for which this happens less frequently. Importing is most cost-effective for mass production, especially for small, compact products that are already available from a given manufacturer (listed in their catalog).

All the issues considered here concern companies, not shipments for individual customers.

Are you considering transferring production from China to Poland? Consult the project with us, and our engineers will advise whether it will be possible.